WE FOCUS ON PROVIDING OUR CLIENTS REQUIRED SERVICES QUICKLY, EFFICIENTLY AND HONESTLY.

Uniq-RM is a multipolymer system that improves rheological properties, optimizes filtrate control and

cake quality, improves emulsion stability and increases lubricity in all oil-based fluids. The lower torque, drag, density and improved cake characteristics provided by this system improves penetration rates, reduces seepage losses and significantly improves production.

Features

- Low solids

- Shear thinning

- Polymer based rheological properties

- Rapid gel development with fragile gel break-back

- Real-Time response to rheology modifiers

Benefits

- Improved rates of penetration

- Reduced pump requirements

- Reliable hole cleaning

- Excellent suspension with lower circulating pressures

- Quick response for well control

UniqEnergy’s “Uniq-RM” oil based, invert emulsion system uses innovative and contemporary oil soluble polymers to provide both broad spectrum rheological properties and optimum filtrate control with superior cake qualities. Commercially treated clays and lignites are not required in this innovative, polymer based oil mud system. The interaction of polymers with the base fluid, in the Uniq-RM invert system, is the key to its robust yet fragile gel structure, providing optimum low-end rheology with superior hole cleaning ability. The gels form quickly to provide optimum suspension when circulation is interrupted and break back immediately when the pumps start or the pipe is lowered into the wellbore, thereby avoiding excessive pump and surge pressures. The Uniq-RM invert system runs with reduced commercial clay content without compromising carrying capacity, while completely avoiding the problem of overtreatment with slow-yielding organophilic clays that often leads to costly lost time and excessively thick mud with high circulating and surge pressures.

Thin Filter Cake

The extremely thin filter cake and low volume of fluid invasion provides optimal logging conditions, superior return permeability and requires low lift-off pressures.

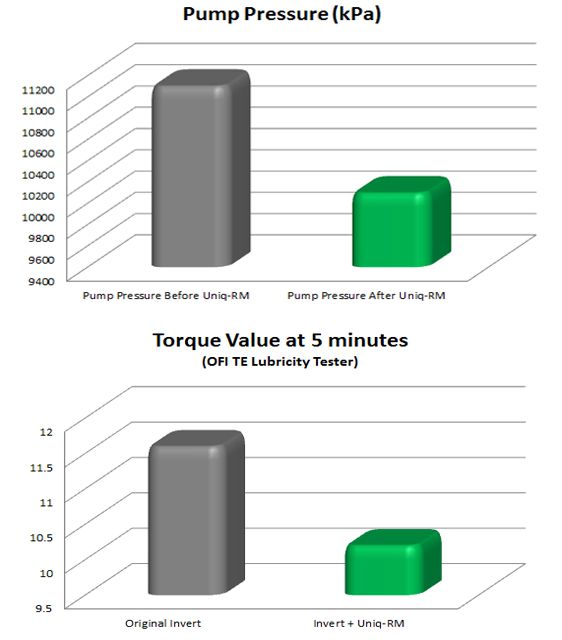

Reduced Pump Pressures

Due to its excellent shear thinning characteristics, lower solids content and fragile gel strengths the Uniq-RM system requires lower pump pressures than conventional oil based mud systems. Because the fluid rheology is achieved without clay, higher plastic viscosity values do not result in increased pump and surge pressures.

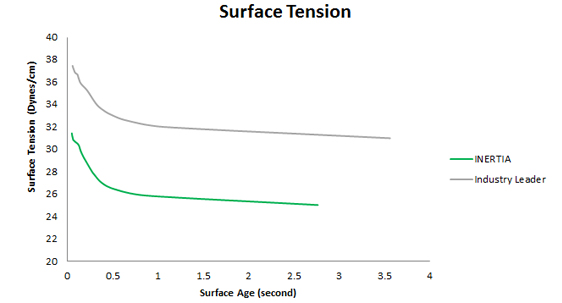

Inertia is a unique blend of amphillic surfactants and solvents engineered to minimize surface tension between polar and non-polar liquids. Inertia minimizes the blocking of pore throat capillaries due to filtrate invasion.

Inertia is engineered to lower interfacial tension, on a molecular level, between water or acid/water and oil phases thereby reducing capillary pressure and substantially improving production.

Inertia can be used in drilling fluids, fracturing packages or water based stimulation packages to increase flow-back and production. Inertia can be easily blended into most commercial acid packages and is compatible with most acid system additives.

Inertia enhances production substantially in under pressured reservoirs giving new life to old wells Inertia preserves O/W wettability in all formations and provides substantially increased production with reduced pressure requirements by improving flow through capillaries and constricted pore-throats.

- Reduced capillary pressure

- Preserved wettability

- Miscible with both acid and water systems

- Stable over a wide pH range

- Reduced o/w interfacial tension

- Increased/prolonged production

- Cost effective in low concentrations

- Compatible with most acid/water additives

- Greater production at reservoir pressure

Product loss, due to inadequate mixing facilities and poor dispersion of polymers, is a major contributor to cost and lost time, which also equates to lost production. The highly dispersible nature of UniqEnergy polymers minimizes mixing problems and provides maximum properties at minimum concentrations and cost without needless product loss over the shakers.

- Optimum Properties

- Lower overall product cost

- Less time spent mixing

- Total dispersibility

- Lower concentrations

- Time and cost savings

- Minimal product loss over shaker

Horizontal drilling techniques, along with increased open-hole completions, are becoming increasingly popular methods for minimizing costs and optimizing the extraction of hydrocarbons and both bring awareness to the importance of efficient wellbore cleanup.

In a conventional wellbore cleanup operation an acid would be spotted through tubing (or coiled tubing) with non-uniform placement of the acid causing spotty and problematic cleanup (worm holes, gas coning, water breakthrough etc.).

Rapid acting acids like HCl do not provide uniform mud cake removal and residual filter cake reduces well productivity and value.

Highly reactive liquid acids leak off into weak spots causing worm holes and uneven cleanup rather than treating the whole interval and removing the mud cake evenly.

Conventional acids like 15% HCl are hazardous to handle and require the use of costly and environmentally unacceptable corrosion inhibitors making completions and residual cleanup complex, costly and dangerous.

- Syncura uniformly removes filter cake in long horizontal and highly deviated wellbores optimizing toe to heel production.

- Syncura in-situ acid production improves fluid placement, uniformly dissolving carbonates in the mud cake across the entire wellbore face.

- Syncura is a solid non-toxic powder which is packaged in bags, minimizing shipping, handling and cold weather freezing/gelation problems.

- Syncura can be mixed and spotted using conventional rig mixing and pumping equipment reducing time and the need for expensive

- Syncura improves mud cake removal for horizontal wells where lower draw down limits the wells ability to self-clean.

- Syncura does not require expensive or complex post disposal methods.

- Syncura ensures that new wells produce to their maximum potential or can be used as a remedial treatment for old underperforming wells.

- Syncura ensures complete treatment (achieving uniform radial and longitudinal coverage) resulting in optimal production throughout the production interval.

- Syncura improves and maintains permeability throughout the pay zone.

- Syncura provides for uniform interval production and does not cause worm holing, gas coning or water breakthrough.

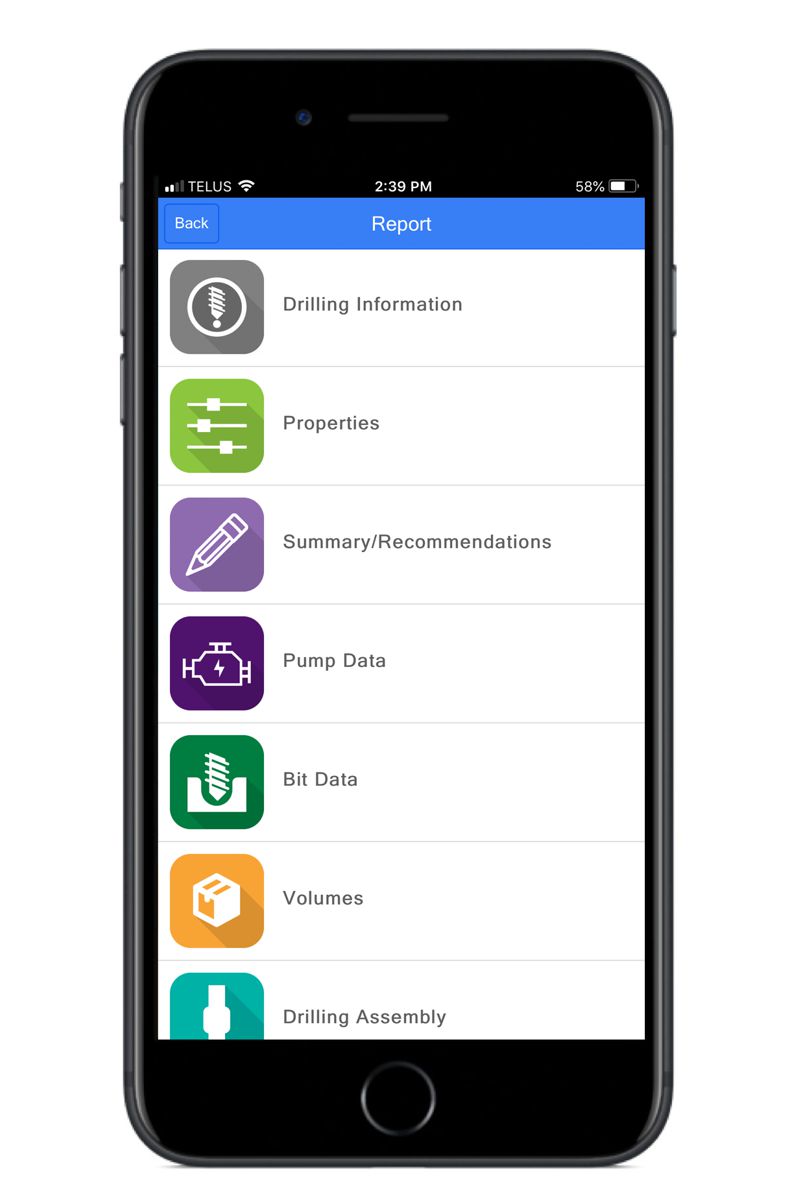

The accessibility of data is paramount is being able to quickly review and analyze current well activity.

UniqEnergy has developed a reporting application, for both iOS and Android, which allows the account manager or operations to approve and comment on a report prior to the client receiving it. Upon report approval, the data instantaneously appears on the client’s side. Data is set to be push through, so the client will be notified of the uploaded report. Upon logging in, the client will be presented with a map and list of their wells. Selecting a well will provide the client with an immediate snapshot of the current well activities. Editable tabs allow the client the flexibility of selecting what they’d like to see first.

PDF reports may also be provided via email, should the client prefer to read the full report. The full reports can also be selected, shared and printed from within the application.

- The industries first drilling fluids reporting app

- Ability to quickly review and analyse current activity

- Easily view the latest fluid properties

- 24/7 client access to all mud reports

- Customizable well dashboard

- Provides the current daily and cumulative cost